Home › Forums › General discussions › Scratched Glass

- This topic has 43 replies, 4 voices, and was last updated 4 years, 1 month ago by

Scudie.

-

AuthorPosts

-

-

5 February 2021 at 19 h 04 min #48362

Scudie

ParticipantWas wondering if any one had any experience in polishing out scratches in glass?

I have made a start on a Seeburg SC that some one has started to scratch something onto the front glass, looks a bit like a capital L , any how I can’t make my mind up if it would be quicker and easier to get a new piece cut and replace it, I can mask off and paint the black & gold section at the bottom but I would loose the lettering at the top or to have a go at polishing out the scratches.

Any tips would be appreciated

Cheers Scudie

-

6 February 2021 at 15 h 22 min #48363

Randy

ParticipantWell. I have had decent luck on tempered glass with a pumice based hand cleaner or jeweler’s rouge/mild polishing compound and a handheld rotary tool. Not sure if the SC glass is tempered, I can’t find a place around here that will cut tempered that small. I would practice on a bit of scrap glass before doing the box though.

Randy

-

6 February 2021 at 20 h 29 min #48366

Scudie

ParticipantHi Randy

Dont know if it’s tempered or not, I know the side glasses just crack when damaged am guessing if temped they would shatter into little bits ?

I think I will give it a rub with some abrasive paper as the scratches can be felt with my finger nail so are fairly deep. Once I can’t feel them I’ll go to a finer and finer grade till I get to 1200 or 1500 then I will try polishing it.

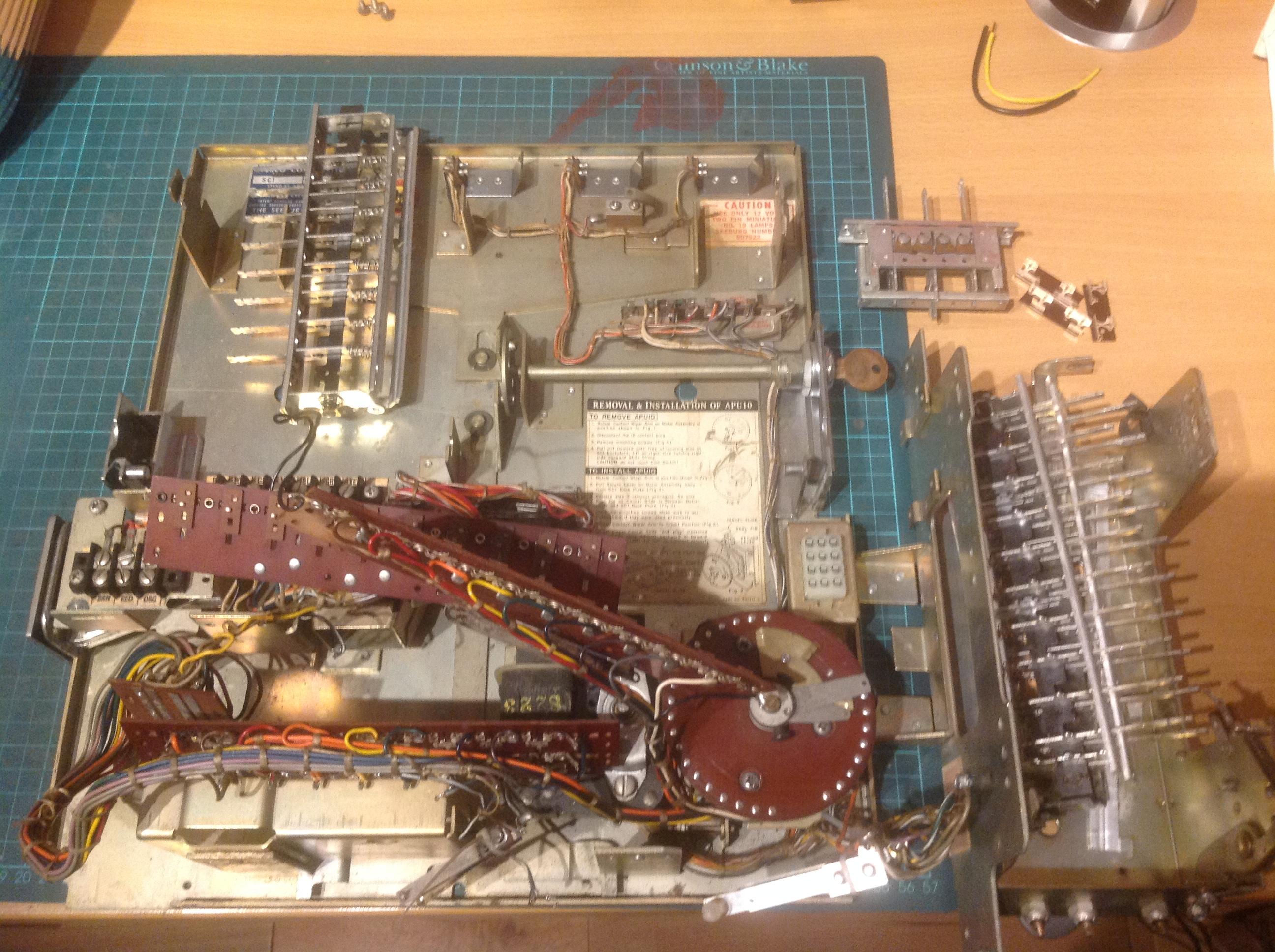

Probably be a day or two befor I get around to doing it as I stripped the SC today as the only number buttons I could press was 1 & 8 the number switch bank was that distorted that the other six actuating plates totally missed the holes that the should pass through.

-

This reply was modified 4 years, 1 month ago by

Scudie.

-

This reply was modified 4 years, 1 month ago by

-

7 February 2021 at 0 h 53 min #48369

Randy

ParticipantThat is certainly stripped! Wonder what caused that much distortion – I have not encountered anything that severe yet.

-

7 February 2021 at 12 h 37 min #48370

Scudie

ParticipantAfter struggling for a while with my first SC (with unreliable signal pulses) I admitted defeat and stripped it and cleaned all the letter & number contacts.

Some times the buttons can be a pain to remove but they came off fairly easy on this one, the only awkward part of stripping the unit is unsoldering the two wires on the top motor starting switch because access is not great.

But I find that it’s the only way to be able to give the selection switch contacts a thorough scrub in hot water and detergent. After rinsing and drying I leave it overnight in the warm before starting to reassemble.

Cheers Scudie

-

7 February 2021 at 14 h 18 min #48371

Scudie

ParticipantNot sure why but some of my previous post has not been displayed.

I can only assume that the damage occurred either when the unit was shipped.

Or by someone pressing several of the central number buttons simultaneously very hard repeatedly, may be even hammering them with the hand untill the two riveted pieces gave way allowing the rear section to bow out of shape. Who knows it may have been the same low life that started to sign there name on the glass.

I have not seen this kind of damage before, but this SC was also very dirty inside as though it had been stored for some considerable time with no cover on it.

Cheers Scudie

-

7 February 2021 at 16 h 30 min #48372

Randy

ParticipantI am often amazed by how resilient the boxes and pins that I have are considering the abuse some have been through. For some pinball collectors the graffiti is just another bit of the history of the machine but I do not like it on wallboxes. Also, some folks can’t get over how applying a little water to these EM devices is not harmful if done correctly. Here is a good example of cleaning :

Randy

-

8 February 2021 at 12 h 17 min #48373

Scudie

ParticipantInteresting video ! Had not seen that before, I use a detergent called Actiwash & spray it on using a basic hand trigger spray bottle then agitate the area with an old toothbrush, it would be great to have a large sink as in the video, I make do with an old cut down 25 litre plastic container sat on my foldable work bench.

Because I strip the box to the point shown in the photo I am able to clean specific areas without affecting any paper labels or soaking the motor.

When I got my 3WA the motor ran very slowly so I removed it and stripped it down so I could clean and lubricate as required. While the motor was out of the way I took the opportunity to clean the rest of the wallbox, I think I had to do the same with a 3w1 that was gummed up with grease, but I have never had that problem with the motor on a SC.

Regarding what is sometimes referred to as graffiti & by some as art ! I am afraid that I am of an age that were tought that it was vandalism & a criminal offence to maliciously cause wilful damage or destruction of some one else’s property, quite a few of my teachers had served in the forces during the Second World War & believed that most forms of corporal punishment were way to lenient for the little so and so who had started defacing school property .

I agree with you about it I don’t like to see it on anything whether it’s mine or not.

Interesting to see in the video that free play on the 3wa was achieved by grounding a grey wire near the motor.

Cheers Scudie

-

8 February 2021 at 17 h 41 min #48377

Randy

ParticipantRight, I’m a little particular about the labels and warnings as well. I have become fairly proficient at recreating them – started with pinballs but have done some for boxes as well. Here are some I did for my 3W2-L56 boxes. I print them on adhesive backed vinyl.

-

9 February 2021 at 0 h 55 min #48379

Scudie

ParticipantHi Randy

Well they do look the business, I’m very impressed! As they say the devil is in the detail.

I put the SC back together yesterday afternoon , decide instead of going down the free play route, I would reinstall the credit unit and wire a momentary switch to the coin switches, mount the switch in the coin aperture with a coin glued to the switch Sooner did his like this a while ago, well I have spent hours with that blooming credit unit. I have eventually managed to get 3 credits with two presses of the switch but further presses achieve nothing. Will have to give it more thought.

Or just leave the damn thing out.

Cheers Scudie

-

9 February 2021 at 20 h 56 min #48380

Scudie

ParticipantHi Randy

I guess your SC is working on coins ?

Did you run the AC for the coin switches through a 10 watt 40-50 ohm resistor as per instructions from Data Sync ?

I have eventually got the APU 10 56 working when I operate the quarter lever with my finger and from the quarter coin switch if I give it 25vac but if I connect the the coin switches through the resistor it doesn’t have the strength to lift the detent pawl.

Any suggestions?

Cheers Scudie -

10 February 2021 at 7 h 23 min #48381

Randy

ParticipantHey Scudie – sent you an email.

randy

-

11 February 2021 at 20 h 41 min #48414

Scudie

ParticipantGot the email.

While trying to get the SC credit unit to work I have learnt a few bits about the

APU 10 -56 credit unit.

1 There is a spring that is connected to & wraps arround the lowest of the three credit wheels (nickel wheel) the other end of the Spring is secured to the chassis of the credit unit, it is the action of the credit removing mechanism that turns the credit wheels thereby tensioning the spring.

2 On the top triangular ish plastic cover that is held in place by two screws and a small e clip there are two Spring blades that hold metal pins in place, both the pins and the screws that secure the spring blades can be moved to several different holes, if the springs exert to much pressure on the heads of the pins it can cause the contact quadrent below to bind thus stopping the credit unit working, also depending on which hole the pins are situated they can have both an effect on the electrical circuit and in the case of the outer one it can act as a stop for the quadrant limiting how far the quadrent can move.

3 There are at least two different versions of the credit unit that is fitted to the SC it concerns the spacing of the two screws that secure the credit unit to the chassis of the SC it would appear that on the earlier machines the screws are closer together, closer by approximately half an inch than on the later machines, the later credit units can be fitted to an earlier machine but only one screw can be fitted if an early credit unit is fitted in a later SC.

See photo below.

Cheers Scudie

-

This reply was modified 4 years, 1 month ago by

Scudie.

-

This reply was modified 4 years, 1 month ago by

-

12 February 2021 at 2 h 18 min #48421

Randy

ParticipantThanks Scudie, after reading you email and going back to the manual I think I have the APU issues figured out. Still have not decided I’m going to work this one next – there are other problems with it. I’m out of emulators and waiting on them to restock.

Randy

-

13 February 2021 at 9 h 29 min #48422

Scudie

ParticipantWell have got the credit unit working and the SC back together sufficiently to test it out, on previous SC’s I have manually closed the contacts of the audio control relay and fixed them with a small cable tie to stop them opening, on this one as I am trying to do things a little differently I am going to see if it’s possible to get the relay to operate electrically as it was designed to do.

Cheers Scudie

-

14 February 2021 at 17 h 38 min #48453

Randy

ParticipantI am very interested in a solution for the audio control. I would really like to be able to control volume as the box was designed to.

randy

-

14 February 2021 at 19 h 50 min #48456

Scudie

ParticipantOk so the audio control relay , the relay is grounded by WG contact of latch bar cam switch while the wiper arm is turning but once the wiper arm has come to rest the relay looses its ground connection and the relay drops out and the contacts open so the audio circuit is broken.

Part of the winding of the relay is connected to the terminal board marked VIO and is shown in the manual as Relay Audio control ground, if this connection is grounded the relay remains energised when the wiper arm has come to rest but the relay stays energised until either the AC or the ground cicuit is cut.

I am guessing that originally this relay probably would not be energised for more than half an hour or so (the length of time it would take to play ) one side of an album.

I assume that the terminal marked VIO would have originally been grounded by the phono probably part of the stepper unit.

-

14 February 2021 at 20 h 50 min #48457

Scudie

ParticipantSo I had the idea to fit a switch that would make when released and to fit this to the end of the credit unit so as the contact quadrent returned to the no credit position it would activate the switch cutting the ground connection thus the relay would drop out, unfortunately it would do this as the last selection was made thus the last selection would not be heard.

As of yet I have not figured a way arround this problem which is disappointing, unless any one else can come up with a workable solution ?

Cheers Scudie

-

14 February 2021 at 22 h 44 min #48458

Sooner

ParticipantRandy – I use a 20 ohm 5 watt resistor in front of the coin relays although I think a 10 ohm would also work and probably reduce the buzzing “chatter” when the relays are engaged.

Scudie – I’ve always found the credit unit to be the most troublesome to adjust and usually need a good cleaning. Good to have one in proper working order to refer too. I’m pretty sure it’s been responsible for incorrect selections too, although I’m not sure why. Also I just bypass the stupid audio cutoff relay and call it good. 🙂

-

15 February 2021 at 6 h 25 min #48459

Randy

ParticipantThanks Sooner, I’ll take a look at that, with the two SCs I have on one I used the Data Sync solution and the other came with a 6/10 fuse wired the same way. I have noticed the “chatter” on both. I have to say the SCs have proven more problematic than any of the other EM boxes I have worked on.

Randy

-

-

15 February 2021 at 10 h 41 min #48460

Scudie

ParticipantI think I am ok with the credit unit & how it’s set up now, I have currently got it set up so a single press of the quarter coin switch is generally giving me 5 credits , I have moved the two grey wires from the # 8 position singles to #8 albums on the board, with a single quarter registered if any of the #8 selections are made nothing happens, if I press the switch so it has had two quarters registered then the #8s will play and the credit unit removes all credit for the single #8 selection.

I would really like to find a solution to the audio relay problem, will have to give it more thought, I may get arround to having a go at the scratched glass today!

-

17 February 2021 at 10 h 50 min #48461

Scudie

ParticipantOk so I have had a go at the scratched glass as I said the damage was quite deep and could be felt. After finding a piece of dense polystyrene to place the glass on I started with a piece of 400 grit wet and dry paper on an electric sander and a small amount of water on the glass after ten minutes of sanding it had made very little difference if any! to the glass, so swapped to 320 grit paper ten more minutes sanding again made no visible difference, so swapped the paper for a diamond sharpening stone that’s made for sharpening wood chisels.

This did the trick! although it probably took an hour or so of rubbing to reach the point that the damage had virtually disappeared however it also hi lighted the fact that there were other areas of damage. I carried on for another hour or so with the diamond sharpening stone again using a little water with it. I eventually called it a day and left the glass on the polystyrene for the night!

So the next day I went back to it with the intention of polishing up the glass with a kit that I bought, unfortunately it would appear that the decals that Seeburg used on the inside surface of the glass especially the SEEBURG CONSOLETTE lettering do not like being left overnight on a wet surface as when I lifted the glass to inspect my previous nights efforts half of the lettering was missing / displaced.

As the whole point of this was to re use the glass with its original lettering intact it now seems fairly pointless spending hours trying to polish the glass when for a few pounds I can buy a new piece & fairly easily mask off and replicate the black and gold lines at the base.

Cheers Scudie

-

This reply was modified 4 years, 1 month ago by

Scudie.

-

This reply was modified 4 years, 1 month ago by

-

17 February 2021 at 22 h 20 min #48463

Randy

ParticipantNuts, sorry to hear that. I thought the original glass was silk screened and would have held up better. I hoped that they considered that operators would occasionally have to clean the inside of the glass just to remove cigarette smoke residue. On the other hand, now we know to be careful when cleaning the back side.

-

17 February 2021 at 22 h 38 min #48464

Scudie

ParticipantWill chalk that one down to experience, will try to pop into glass merchants tomorrow and get a new piece.

Started on the page unit all the pages were as per well stuck together, have removed all the old sticky labels & glue residue will print some new ones later.

Got to find some replacement Turn Page black plastic labels or the pricing ones as there’s half of them missing. I Seem to remember some one printing some on photo paper?

Cheers Scudie

-

17 February 2021 at 23 h 00 min #48465

Randy

ParticipantWhoever designed those selection labels did not have a long term view in mind. I had to repaint all the pages after removing the labels. I put together some replacements on MS PowerPoint that printed out pretty well. I printed them on Printable Transparent Sticker Paper and used a paper cutter to get them to the right size – was happy with the result. I’ll email the to you as .png you should be able to size them properly. Also just photocopied the turn page/pricing labels I’ll send you that as well.

Randy

-

18 February 2021 at 2 h 49 min #48466

Sooner

ParticipantScudie – Glossy photocopy paper works great to replace the black labels. I have jpeg files too if you need.

-

18 February 2021 at 6 h 40 min #48468

Randy

ParticipantA guy on Ebay sold me an incomplete set of NOS black labels so with the good ones I already had I had enough for the two SCs I’ve got. I deleted the Album selection labels though – I only wanted single song selections.

-

18 February 2021 at 18 h 34 min #48477

Scudie

ParticipantHi Chaps

Thanks to you both for your suggestions / advice.

I did try copying the black instruction strips but when printed they came out bigger than the originals, not sure why ? any files that you have that you think might help with recreating them would be great & thanks.

Randy after you printed on Printable Transparent Sticker Paper did you then stick this to something else?

Cheers Scudie

-

18 February 2021 at 19 h 06 min #48478

Randy

ParticipantNope, just cut them to size, peeled of the backing and stuck them on the metal.

-

18 February 2021 at 21 h 53 min #48479

Sooner

Participant

-

18 February 2021 at 21 h 55 min #48480

Sooner

ParticipantI printed the ones above on 4×6 photo paper. Don’t recall if it was borderless and/or “fit to page” or not.

-

18 February 2021 at 21 h 58 min #48481

Sooner

ParticipantHere are some others I made up for a friend who wanted vintage “advertisements” instead of pricing and instructions…

-

18 February 2021 at 21 h 59 min #48482

Sooner

Participant

-

18 February 2021 at 22 h 21 min #48483

-

23 February 2021 at 22 h 06 min #48485

Scudie

ParticipantHi folks

Have found a bit of time to make some progress with the SC1, the page unit now has new title strip selection letter/ numbers printed onto sticky backed label paper, the black instruction strips I scanned the originals again and after a little messing about managed to copy and paste another 10 onto the sheet after yet more messing I managed to resize them so when printed onto glossy photo paper they actually came out a very similar size to the originals.

Still got to sort out some 5mm glass for the front cover, as I have been distracted recently with decorating etc.

Randy thanks for the emails, I think I have suitably resized the the Seeburg Consolette script, when I have the new glass I will print it onto some clear sticky vinyl that I have.

Sooner if you have the advert versions of the black strips that you posted, in a format that prints out the correct size I wouldn’t mind a copy if you don’t mind.

Cheers Scudie

-

24 February 2021 at 1 h 19 min #48486

Randy

ParticipantLooks good Scudie, did you go with the white backed selection numbers/letters to make them easier to see?

-

24 February 2021 at 11 h 10 min #48487

Scudie

ParticipantHi Randy

I did print a set off on the standard white label paper but thought they looked a bit stark too clinical . So printed a set with a pale yellow background in my opinion it looks better.

On the first SC’ I did the page unit was ok not perfect but useable, on all the subsequent ones the pages have been stuck together so have been cleaning all the labels and glue residu off and replacing them with the sticky label version that I used on the above photo.

Cheers Scudie

-

25 February 2021 at 10 h 58 min #48536

Sooner

ParticipantScudie – I sent you an email with the files although you should be able to copy and paste the ones above a jpeg file and print to the correct size. May take some trial and error as I don’t recall if I used the “fit to page” and/or borderless options when I did them.

-

26 February 2021 at 19 h 27 min #48569

Klaatu

KeymasterWould be great to create a new topic with all your scanned cards or ads, so that it can be found easily, if files are too big, I can upload them to the server.

-

4 March 2021 at 12 h 35 min #48584

Scudie

ParticipantOk have now had chance to clean up the front cover for the SC. When I washed the cover the speaker grills came away I put them in some strong detergent over night, some of the glue and black paint from the cover washed off but the grills had patches of a yellow/gold colour that were still evident when viewed from the front.

I tried several different products to clean these patches off, I tried a couple of adhesive solvents but these had no affect, I eventually found that paint stripper did the trick.

-

4 March 2021 at 13 h 45 min #48586

Scudie

ParticipantI also noticed that this chrome cover differs in design to other Seeburg SC’s that I have seen, in particular in the way that the two side glasses are held in place, on all of my previous SC’s the chrome metal plate that holds the side glass in place is held by just two screws & by a tongue on the plate that locates in a slot on the front cover.

This one has no slots on the front cover and the lower section of the plate is clamped by a long 20 mm or so 3rd screw that holds a 90° angle to the side of the case.-

This reply was modified 4 years, 1 month ago by

Scudie.

-

This reply was modified 4 years, 1 month ago by

-

4 March 2021 at 14 h 03 min #48588

Scudie

Participant

-

4 March 2021 at 22 h 28 min #48589

Randy

ParticipantRight, neither of the ones I have are like that. Wonder what prompted the variation? I recently ran across an ad for another variant. I have yet to see one with a call button.

-

5 March 2021 at 11 h 19 min #48590

Scudie

ParticipantHi Randy

I was aware that Seeburg had built the con com as I have seen photos of them, infact a guy I have bought from advertised a large amount of wallbox’s & jukebox’s in one of the photos was one with the red button, by the time I got there at the weekend he had sold some of the items and it was gone.

I guess unless you also had the base unit it wouldn’t be of any use anyway.

In regards to the front cover I am not sure which is the earlier or later design, as all the covers for the SC and SCH models are interchangeable, you can’t rely on the serial number on the chassis.

Cheers Scudie

-

-

AuthorPosts

- You must be logged in to reply to this topic.